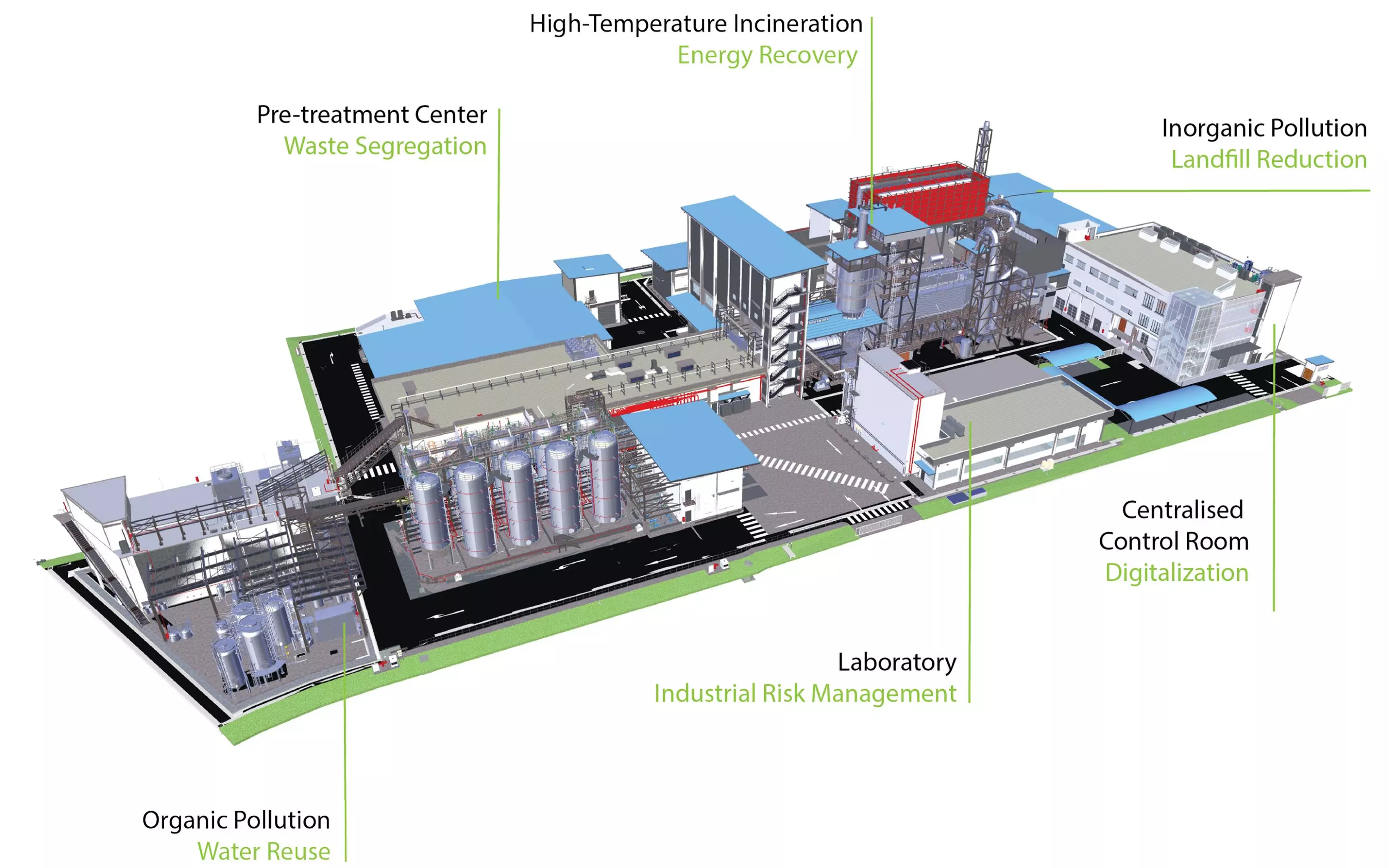

Our facility in Tuas

Our facility is built on four non-negotiable principles that guide all our actions. We follow the waste hierarchy, constantly innovating to shift from disposal to recovery, recycling, reuse, and reduction. Our approach is rooted in continuous improvement, aiming to boost resource efficiency and support circular solutions.

Water Reuse

Organic Pollution

Our treatment systems convert aqueous waste streams into a source of industrial water for our site, reducing water consumption and the quantity of trade effluent discharged to the sewer.

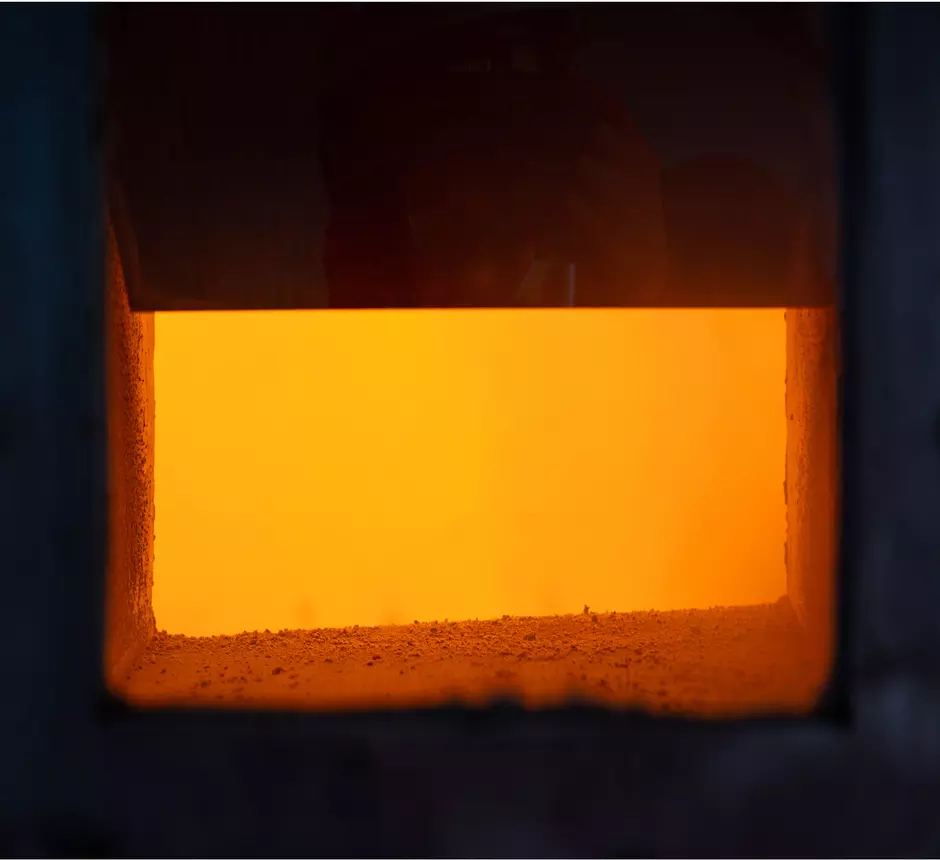

Energy Recovery

High temperature Incineration

High-Temperature Incineration safely destroys hazardous substances while generating energy, supporting facility sustainability.

Landfill reduction

Inorganic Pollution

Our waste segregation operating philosophy enables inorganic waste to be processed through physical & chemical techniques, and stabilisation, resulting in minimum residues disposed of to landfill.

Waste Segregation

Pre-treatment center

The waste segregation carried out by our chemists is a key step to optimize treatment processes - energy recovery, water reuse & landfill reduction - and to ensure regulatory compliance.

Industrial Risk Management

Laboratory

Our 2 On-site laboratories ensure safety and traceability through waste analysis, proper classification, and treatment compatibility testing.

Digitalization

Centralised control room

Our facility features integrated information systems and big data management. This digitalisation gives a real time 360° view on operational situations, supports our journey to operational excellence, and enables AI initiatives.

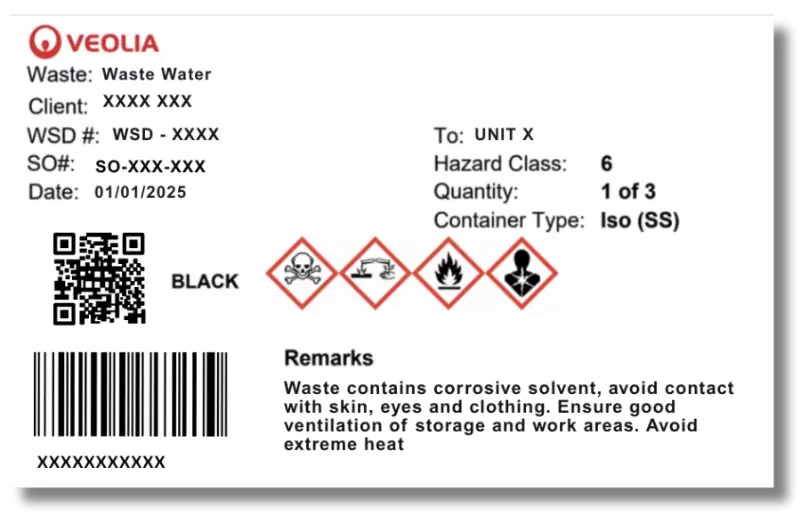

Waste Pre-Acceptance

At the commercial stage, our expert chemists carry out a full panel analysis of all waste streams to understand its composition, the associated industrial risks (including compatibility): an identification number (WSD nb) and a treatment route are assigned to the waste.

Waste Collection

Upon customer request, waste collection service is triggered, using appropriate containers and vehicles, strictly following safety procedures. This involves conducting risk assessments, controlling spills, proper labeling, and ensuring trained personnel wear appropriate PPE.

Waste Storage

At the waste reception stage, a “Post-acceptance” analysis is carried out at the laboratory, for all incoming waste. A comparison with the Pre-acceptance analysis supports the dispatching decision: final treatment route & storage zone, tank or building, in full traceability at every stage.

Waste Treatment

Thanks to our traceability system and a centralised data management, operational and laboratory teams adjust the treatment schedules on daily basis, following a compass: maximising reuse, reducing incineration when possible, minimizing landfill all the time.

Traceability

to built trust

Our information systems are specifically designed to support a proven HazWaste management process

A waste generated by a customer’s site is assigned a unique identification number (WSD number). When a collection service is requested, the WSD number is linked to a unique service order number: this unique pair of identification numbers will constitute the base of the traceability in our systems. From an operational point of view, this traceability translates into a labels and barcode/QRcode which displays necessary information for safe handling.

Our Full Range

of Services

Explore how our tailored solutions in Hazardous Waste Management can meet the unique needs of your operations

CONTACT US

How can we help you?

Our dedicated experts are here to address your waste, water and energy challenges and ensure compliant and safe management.